High nickel alloys are a specialized group of materials engineered for extreme environments where standard stainless steels often fall short. While stainless steels typically contain 8–12% nickel to enhance corrosion resistance and toughness, high nickel alloys exceed 30% nickel content and are designed for superior performance in aggressive chemical, thermal, and mechanical conditions. This elevated nickel content imparts greater resistance to oxidation, carburization, chloride stress-corrosion cracking, and other forms of degradation.

Stainless steel and high nickel alloys are related through their shared use of nickel as a key alloying element; in fact, many high-performance stainless steels serve as a transition point between conventional stainless grades and full high nickel systems. However, high nickel alloys distinguish themselves by their broader resistance spectrum and durability in high-temperature or highly corrosive environments.

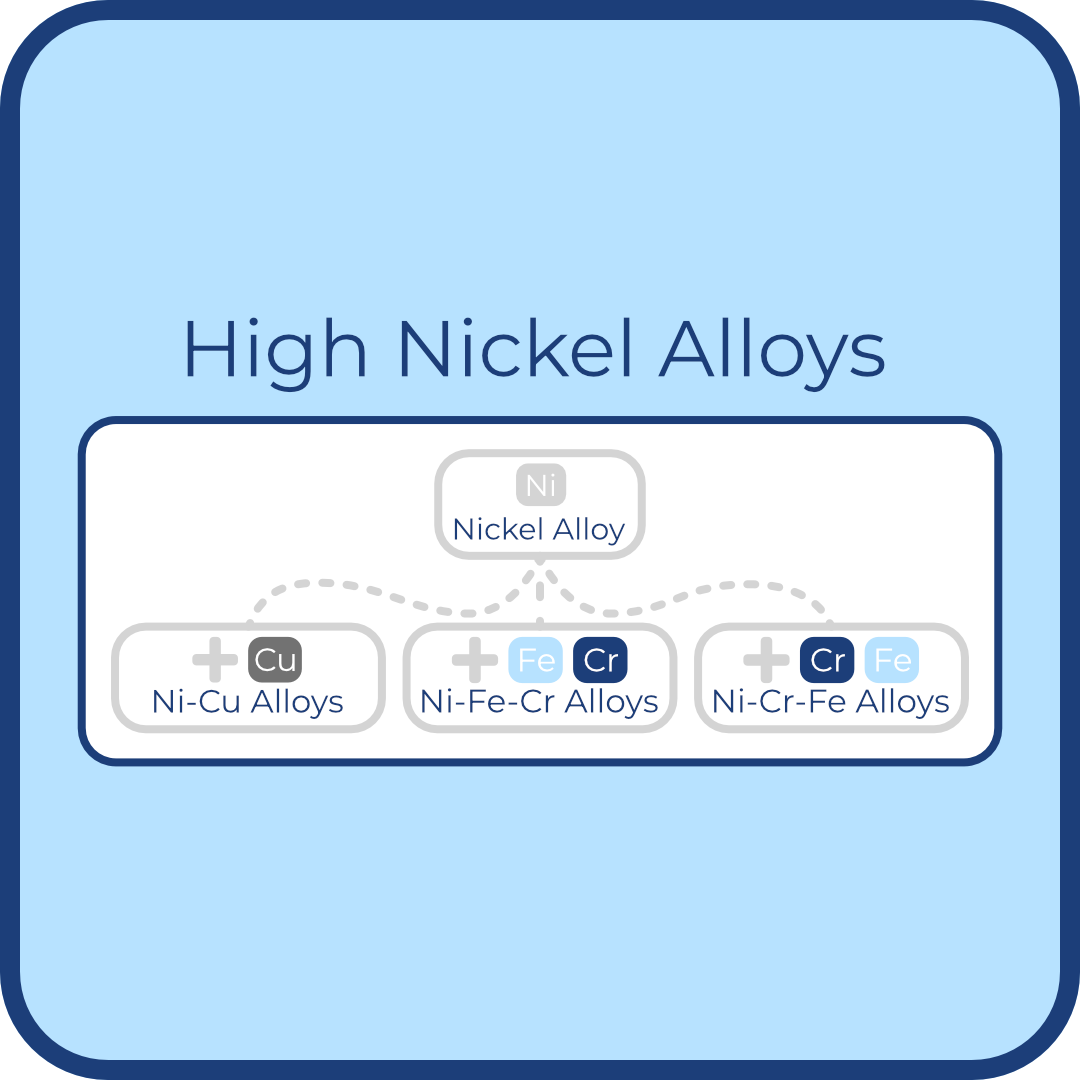

This article will examine the major families of high nickel alloys, including Monel, Inconel, and Hastelloy, and highlight their advantages over stainless steel in critical industrial applications.