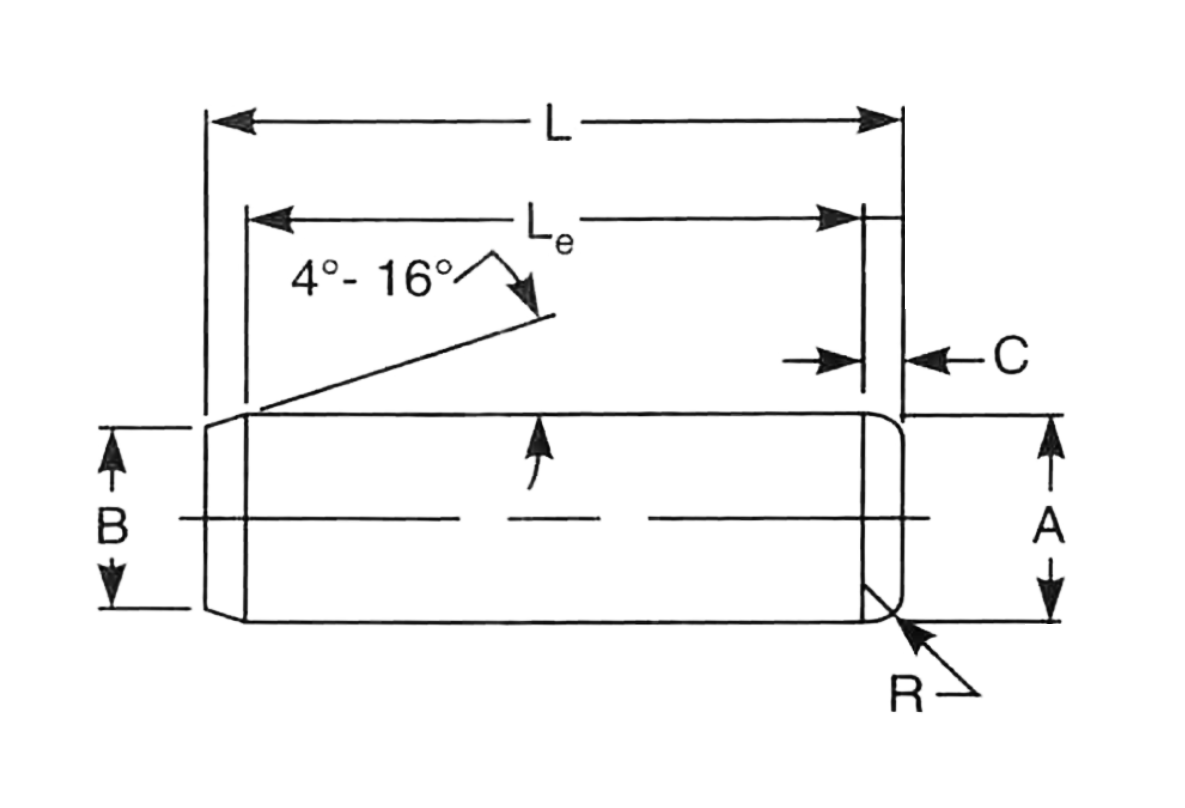

Dimensions

|

||||||||||

| Nominal Size |

A | B |

C | R | ||||||

| Pin Diameter |

Point Diameter |

Crown Height |

Crown Radius |

|||||||

| Standard Series Pins |

Oversized Series Pins |

|||||||||

| Basic | Max. | Min. | Basic | Max. | Min. | Max. | Min. | Max. | Min. | |

| 1/16 (0.0625) | 0.0627 | 0.0628 | 0.0626 | 0.0635 | 0.0636 | 0.0634 | 0.058 | 0.048 | 0.020 | 0.008 |

| 5/64 (0.0781) | 0.0783 | 0.0784 | 0.0782 | 0.0791 | 0.0.792 | 0.0790 | 0.0.74 | 0.064 | 0.026 | 0.010 |

| 3/32 (0.0938) | 0.0940 | 0.0941 | 0.0939 | 0.0948 | 0.0949 | 0.0947 | 0.089 | 0.079 | 0.031 | 0.012 |

| 1/8 (0.1250) | 0.1252 | 0.1253 | 0.1251 | 0.1260 | 0.1261 | 0.1259 | 0.120 | 0.110 | 0.041 | 0.016 |

| 5/32 (0.1562) | 0.1564 | 0.1565 | 0.1563 | 0.1572 | 0.1573 | 0.5171 | 0.150 | 0.140 | 0.052 | 0.020 |

| 3/16 (0.1875) | 0.1877 | 0.1878 | 0.1876 | 0.1885 | 0.1886 | 0.1884 | 0.180 | 0.170 | 0.062 | 0.023 |

| 1/4 (0.2500) | 0.2502 | 0.2503 | 0.2501 | 0.2510 | 0.2511 | 0.2509 | 0.240 | 0.230 | 0.083 | 0.031 |

| 5/16 (0.3125) | 0.3127 | 0.3128 | 0.3126 | 0.3135 | 0.3136 | 0.3134 | 0.302 | 0.290 | 0.104 | 0.039 |

| 3/8 (0.3750) | 0.3752 | 0.3753 | 0.3751 | 0.3760 | 0.3761 | 0.3759 | 0.365 | 0.350 | 0.125 | 0.047 |

| 7/16 (0.4375) | 0.4378 | 0.4378 | 0.4376 | 0.4385 | 0.4386 | 0.4384 | 0.424 | 0.409 | 0.146 | 0.055 |

| 1/2 (0.5000) | 0.5003 | 0.5003 | 0.5001 | 0.5010 | 0.5011 | 0.5009 | 0.486 | 0.471 | 0.167 | 0.063 |

| 5/8 (0.6250) | 0.6253 | 0.6253 | 0.6251 | 0.6260 | 0.6261 | 0.6259 | 0.611 | 0.595 | 0.208 | 0.078 |

| 3/4 (0.7500) | 0.7503 | 0.7503 | 0.7501 | 0.7510 | 0.7511 | 0.7509 | 0.735 | 0.715 | 0.250 | 0.094 |

| 7/8 (0.8750) | 0.8753 | 0.8753 | 0.8751 | 0.8760 | 0.8761 | 0.8759 | 0.860 | 0.840 | 0.293 | 0.109 |

| 1 (1.0000) | 1.0002 | 1.0003 | 1.0001 | 1.0010 | 1.0011 | 1.0009 | 0.980 | 0.960 | 0.333 | 0.125 |