What Are Washers?

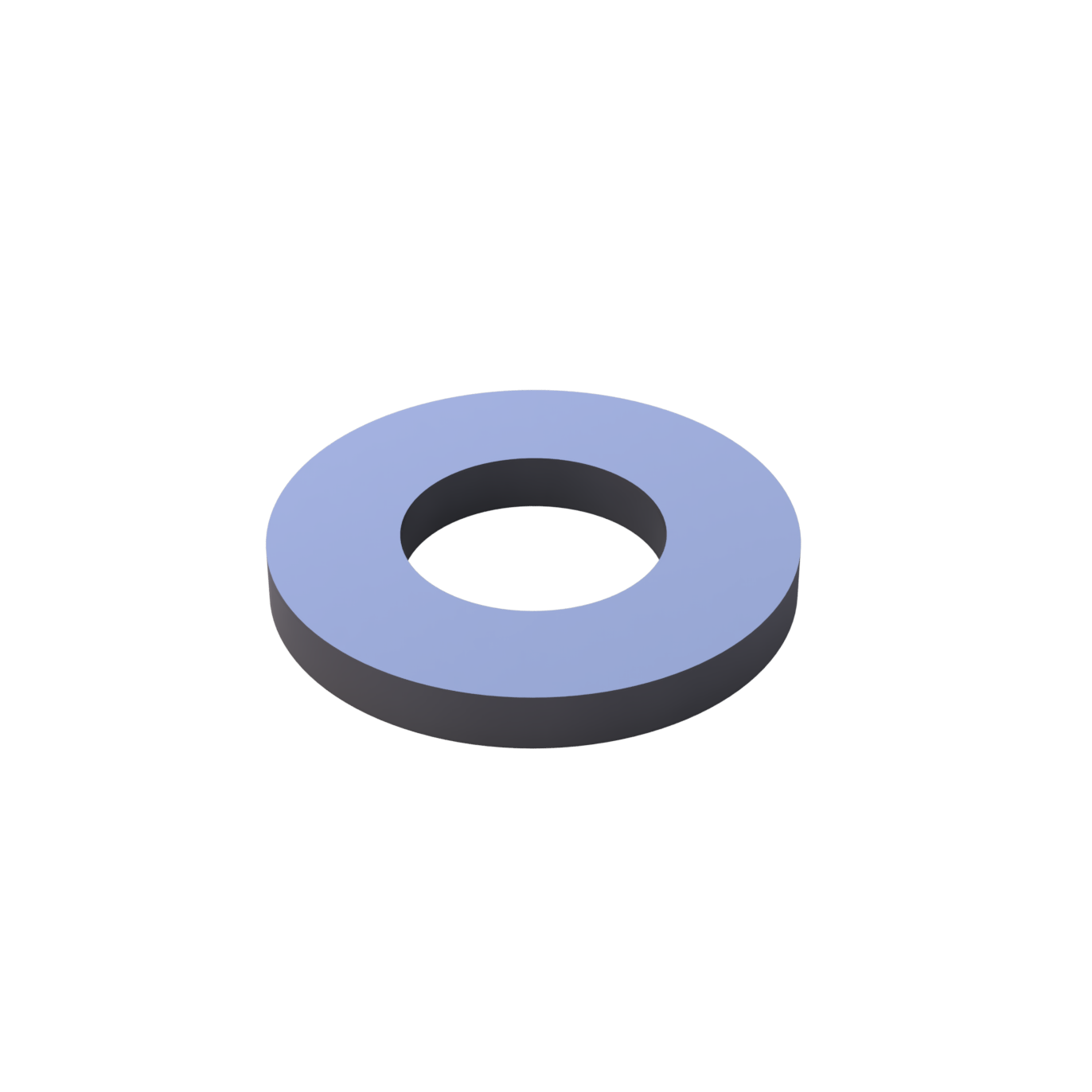

Washers are thin, typically round plates with a hole in the center, used to distribute the load of a threaded fastener such as a bolt or nut. They help protect mating surfaces, reduce vibration-induced loosening and improve joint integrity. Common washer types include:

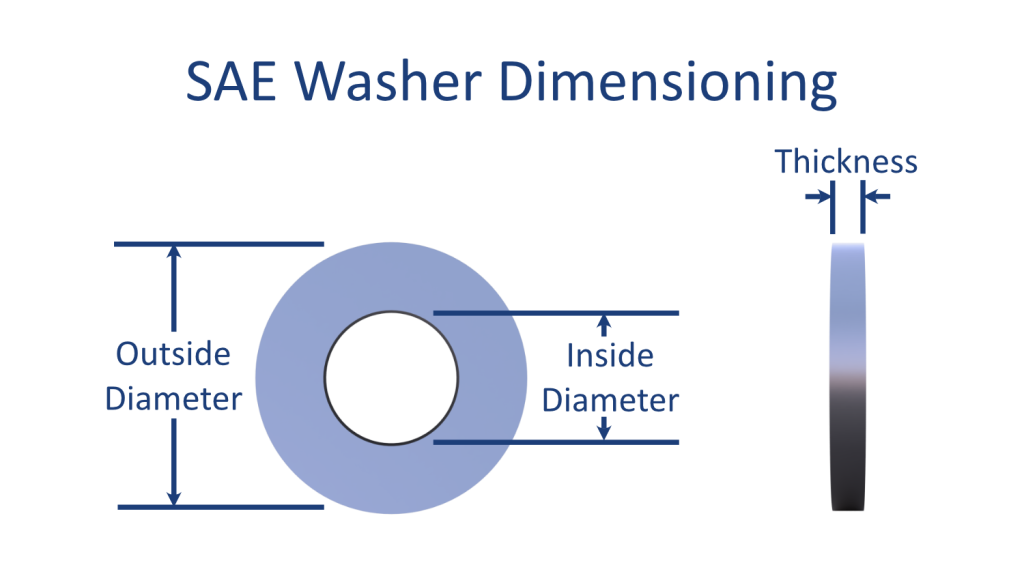

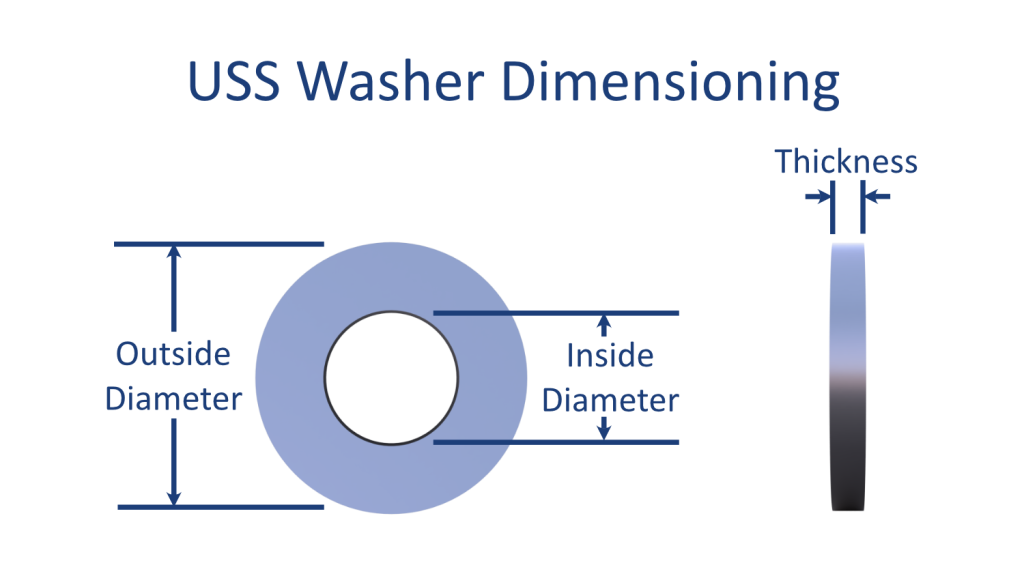

What Are SAE and USS Washers?

USS and SAE are two common dimensional standards for steel flat washers. SAE washers have a smaller outer diameter and thickness, optimized for applications requiring precision fit and space efficiency. They are commonly used with SAE bolts and are ideal for automotive, machinery and fine-thread assemblies where tight tolerances and reduced footprint are priorities.

USS washers feature a larger outer diameter and thickness to increase load distribution and durability. They are ideal for heavy-duty and structural applications, offering better surface protection and resistance to loosening under vibration. USS washers are ideal for construction, industrial machinery and coarse-thread bolt assemblies.

Generally, flat washers made in nonferrous materials do not conform to these standards. In non-steel flat washers, corrosion resistance is usually the primary consideration rather than strength. Additionally, steel is much cheaper than stainless or a nickel-based alloy. Therefore, standard flat washers in nonferrous materials are only as thick or wide as needed to be functional.

Industries and Applications

SAE and USS washers made from exotic alloys help maintain joint security and distribute load efficiently across many critical industries.

Aerospace

SAE washers minimize excess footprint and help maintain consistent torque in lightweight aerospace structures.

- Applications: Airframe components, avionics housings, landing gear

- Materials: Inconel®, Titanium alloys, A286

Automotive

SAE washers are essential in high-performance and space-constrained automotive systems.

- Applications: Engine mounts, gear housings, frame connections

- Materials: Stainless steel, aluminum alloys

Construction

USS washers provide the broad bearing surfaces needed for heavy-duty connections in structural steelwork and building infrastructure.

- Applications: Structural steel joints, bracing systems, bridge assemblies, heavy equipment mounting

- Materials: Stainless steel, AL6XN, Hastelloy®

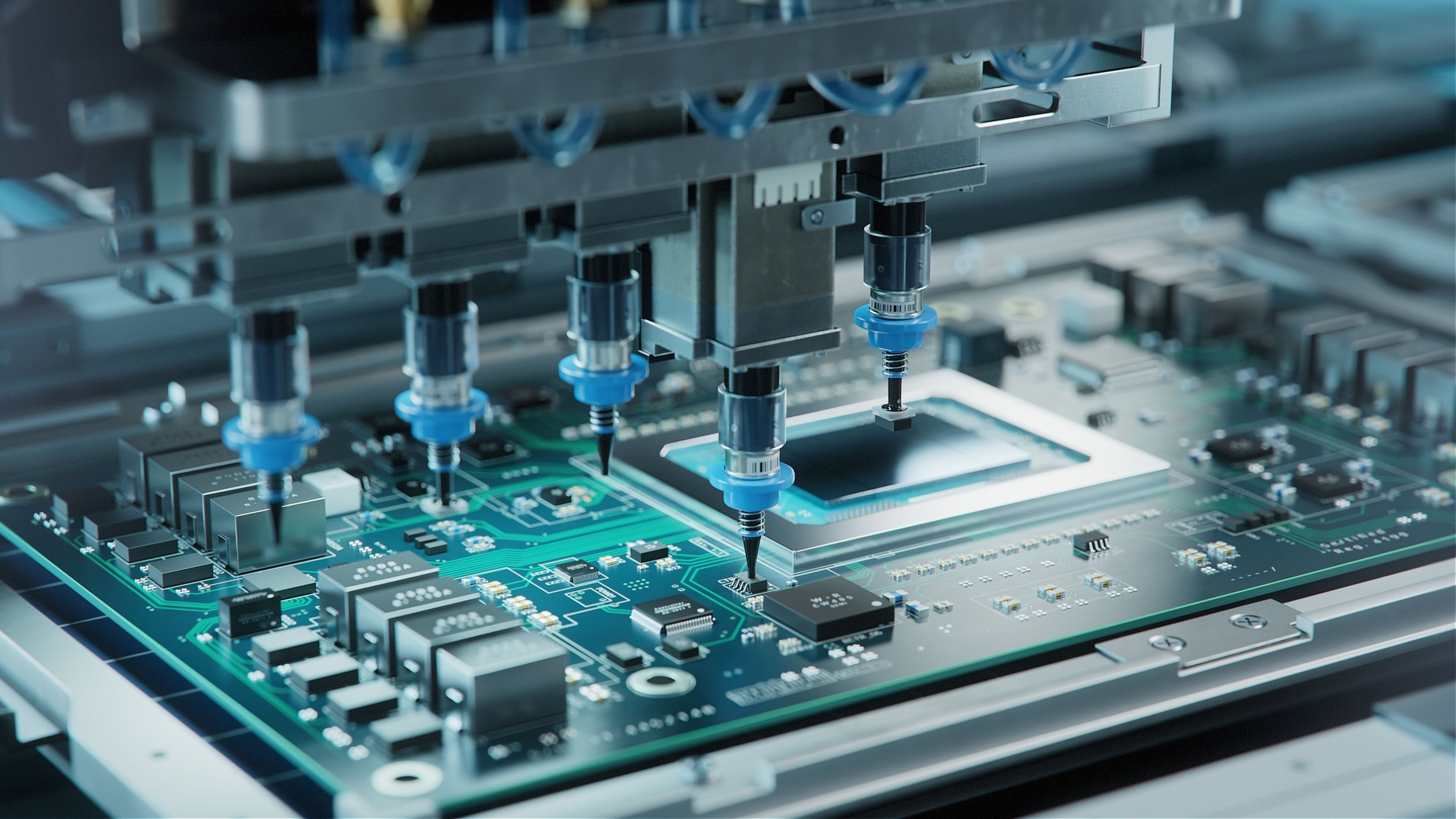

Manufacturing

USS washers help absorb stress in dynamic machinery, while SAE washers support precise positioning in automated or high-tolerance systems.

- Applications: Robotic joints, conveyor systems, hydraulic mountings, tooling

- Materials: Alloy 20, stainless steel

Tips for Purchasing SAE and USS Washers

To achieve optimal performance and long-term reliability, consider these best practices when sourcing SAE and USS washers:

- Verify dimensions: Match washer size, thickness, and internal and external diameters to your fastener and load requirements.

- Evaluate available space and load needs: Opt for USS washers where maximum load distribution is needed. SAE washers are best for precision or space-constrained applications.

- Select appropriate materials: Choose materials based on your application’s needs, from corrosion resistance to temperature exposure and mechanical strength.

- Specify finish or coating: For added corrosion protection or electrical isolation, specify plating or special surface treatments.

- Consult with Nickel Systems experts: For custom or nonstandard sizes, Nickel Systems can accommodate your specifications.