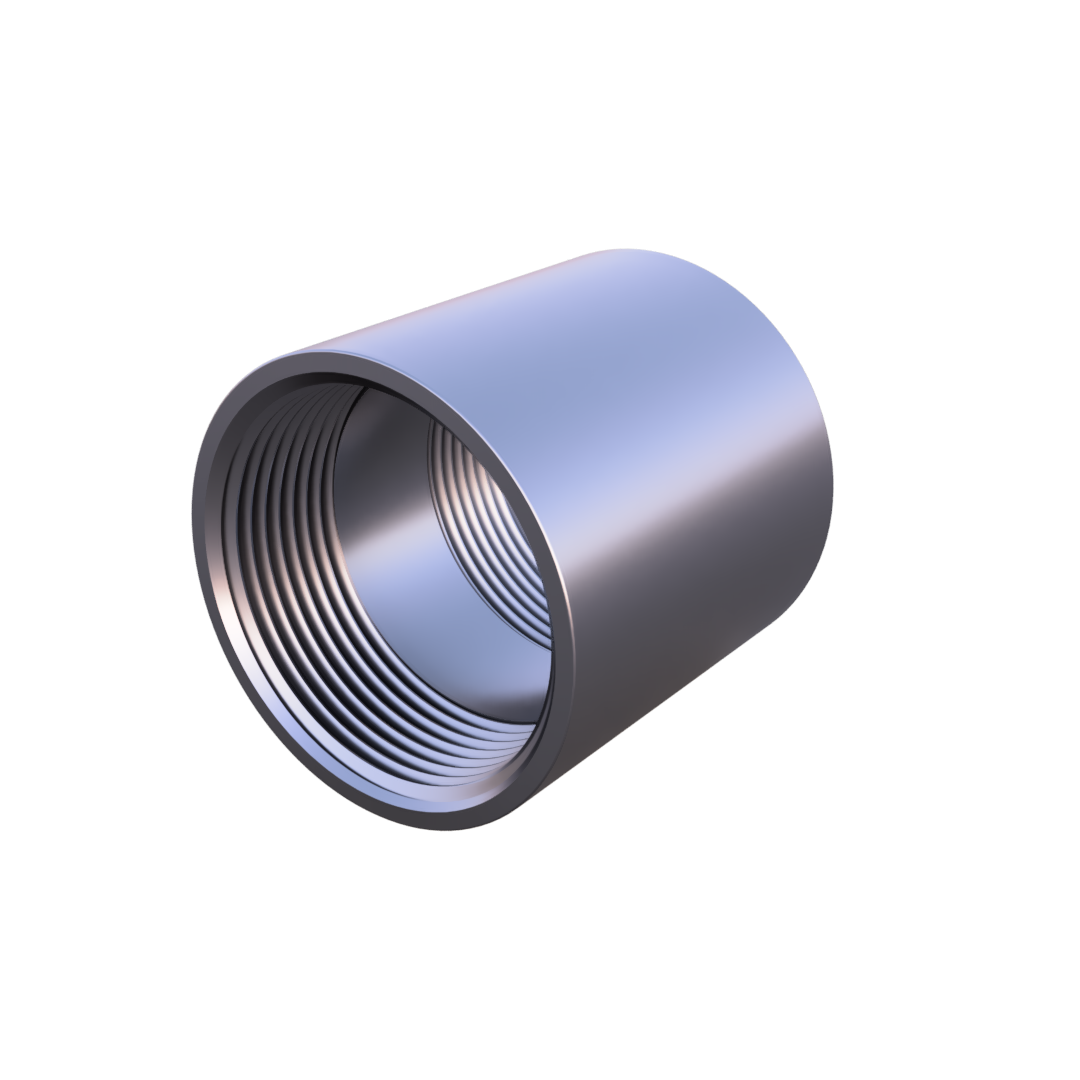

Pipe couplings in exotic alloys play a crucial role in high-performance piping systems across industries such as aerospace, chemical processing, and offshore oil and gas. These couplings are engineered connectors used to join two sections of pipe, ensuring structural integrity and leak-proof operation under extreme conditions. Unlike standard couplings made from carbon or stainless steel, exotic alloy couplings—such as those composed of Inconel, Hastelloy, Monel, or titanium—offer superior resistance to corrosion, high temperatures, and mechanical stress. Their enhanced durability makes them ideal for applications involving aggressive chemicals, high pressures, and thermal cycling. Precision-engineered and often customized for specific environments, these couplings maintain system performance while reducing the risk of failure. As industries continue to push the boundaries of operational environments, the demand for pipe couplings made from exotic alloys is growing, driven by their unmatched reliability, longevity, and ability to meet stringent regulatory and safety standards.