Specifications

- Plate: ASTM A240

- Bar: ASTM A276

Alloy 2205 gets the name Duplex because it is composed of two different types of grains. 40-50% of its grain structure is austenite and 50-60% of it is ferrite. It is closely related to, but much more popular than Alloy 255. In most environments, it surpasses 317L in crevice corrosion resistance. 2205 Duplex excels in chloride environments and resists hydrogen sulfide. 2205 Duplex has almost twice the strength of 316L. Due to the lower nickel and molybdenum content, it is less costly than Alloy C276. Among the places where 2205 Duplex is used include pressure vessels, heat exchangers and scrubbing systems.

Choosing the right materials can make all the difference in industries where reliability and performance are paramount. 2205 Duplex stainless steel offers a robust solution for harsh environments, combining strength and versatility. At Nickel Systems, we understand the critical nature of your applications. We are the largest stocking distributor of exotic alloy fasteners, with a vast inventory that allows us to ship hard-to-find items for immediate delivery.

If your question isn’t answered below, download the technical data sheet here. These specifications and technical data are for CarTech® 2205 Stainless. Cartech® 2205 Stainless is produced by and a trademark of Carpenter Technologies.

| Temperature | ºF | 68 | 212 | 392 | 572 |

|---|---|---|---|---|---|

| Density | lb/in3 | 0.278 | – | – | – |

| Modulus of Elasticity | psi x 106 | 27.6 | 26.1 | 25.4 | 24.9 |

| Linear Expansion (68ºF-T) | 10-6/ºF | – | 7.5 | 7.8 | 8.1 |

| Thermal Conductivity | Btu/h ftºF | 8.7 | 9.2 | 9.8 | 10.4 |

| Heat Capacity | Btu/lb/ºF | 0.112 | 0.119 | 0.127 | 0.134 |

| Electrical Resistivity | Ωin x 10-6 | 33.5 | 35.4 | 37.4 | 39.4 |

| ASTM A 240 | Typical | |

|---|---|---|

| Yield Strength 0.2%, ksi | 65 min. | 74 |

| Tensile Strength, ksi | 90 min. | 105 |

| Elongation, % | 25 min. | 30 |

| Hardness RC | 32 max. | 19 |

| Temperature ºF | 122 | 212 | 392 | 572 |

| Yield Strength 0.2%, ksi | 60 | 52 | 45 | 41 |

| Tensile Strength, ksi | 96 | 90 | 83 | 81 |

| Nitric Acid | Good |

| Phosphoric Acid | Moderate |

| Sodium Hydroxide | Moderate |

| Sea Water | Moderate |

| Humidity | Excellent |

| Sulfuric Acid | Moderate |

| Acetic Acid | Good |

| Salt Spray (NaCl) | Excellent |

| Sour Oil/Gas | Moderate |

| Grade | Corrosion Rate, ipy |

|||||||

|---|---|---|---|---|---|---|---|---|

| Solution A, 140ºF | Solution B, 120ºF | |||||||

| 2205 | 3.1 | 3.9 | ||||||

| 316L | >200 | >200 | ||||||

| 904L | 47 | 6.3 | ||||||

| Composition, wt % | ||||||||

| P2O5 | HCI | HF | H2SO4 | Fe2O3 | Al2O3 | SiO2 | CaO | MgO |

| Sol A 54.0 | 0.06 | 1.1 | 4.1 | 0.27 | 0.17 | 0.10 | 0.20 | 0.70 |

| Sol B 27.5 | 0.34 | 1.3 | 1.72 | 0.4 | 0.01 | 0.3 | 0.02 | – |

| Grade | Boiling | Wick | Boiling |

|---|---|---|---|

| 42% MgCl2 | Test | 25% NaCl | |

| 2205 | F | P | P |

| 254 SMO® | F | P | P |

| Type 316L | F | F | F |

| Type 317L | F | F | F |

| Alloy 904L | F | P or F | P or F |

| Alloy 20 | F | P | P |

(P = Pass, F = Fail)

| Max Forming Temp. (recommended) | 600°F |

| Working Range | 1750° – 2250°F |

| Minimum Annealment Temp. (full solution) | 1900°F |

As industries evolve, the demand for materials that offer durability and cost efficiency grows. 2205 alloy is at the forefront of this demand, providing a balanced solution that meets the needs of various demanding applications.

Alloy 2205 gets the name “Duplex” because it is composed of two different types of grains. 40-50% of its grain structure is austenite and 50-60% of it is ferrite. It is closely related to, but much more popular than Alloy 255. In most environments, it surpasses 317L in crevice corrosion resistance. (See our other blog post on What is Duplex 2205 to get more info.)

2205 Duplex excels in chloride environments and resists hydrogen sulfide. It has almost twice the strength of 316L. Due to the lower nickel and molybdenum content, it is less costly than Alloy C276. Among the places where 2205 Duplex is used include pressure vessels, heat exchangers and scrubbing systems.

2205 Duplex is renowned for its exceptional physical and mechanical properties. It provides high-yield strength, making it an excellent choice for structural applications. Its resistance to corrosion, especially pitting and crevice corrosion in aggressive environments, further enhances its appeal. Additionally, 2205 stainless steel exhibits good weldability and fabrication capabilities, making it suitable for a wide range of industrial applications.

2205 Duplex offers a multitude of benefits that make it a standout choice for demanding applications:

The versatility and unique properties of 2205 Duplex make it an ideal choice for numerous industries where both strength and corrosion resistance are critical. Some of the key applications include:

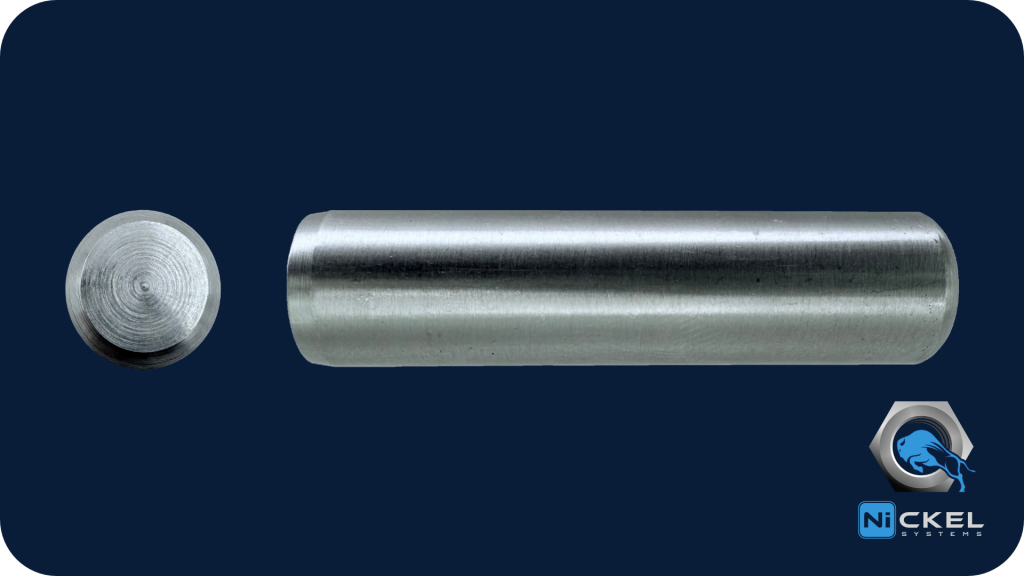

Fasteners play a crucial role in the integrity of any structure or system. At Nickel Systems, we offer a comprehensive range of Duplex 2205 fasteners to meet the diverse requirements of our customers, including:

Check out our 2205 Duplex sample products.