What Are Nuts?

Nuts are internally threaded components that fasten onto bolts, studs or threaded shafts. They transfer load, clamp parts together and maintain assembly clamping force. Standard nuts come in hexagon or square configurations, allowing tools to apply torque for secure fastening.

What Is a Lock Nut?

A lock nut is a type of nut that resists loosening under vibration and torque. It is used in mechanical assemblies to ensure that bolted connections stay tight over time, even when exposed to movement or dynamic loads.

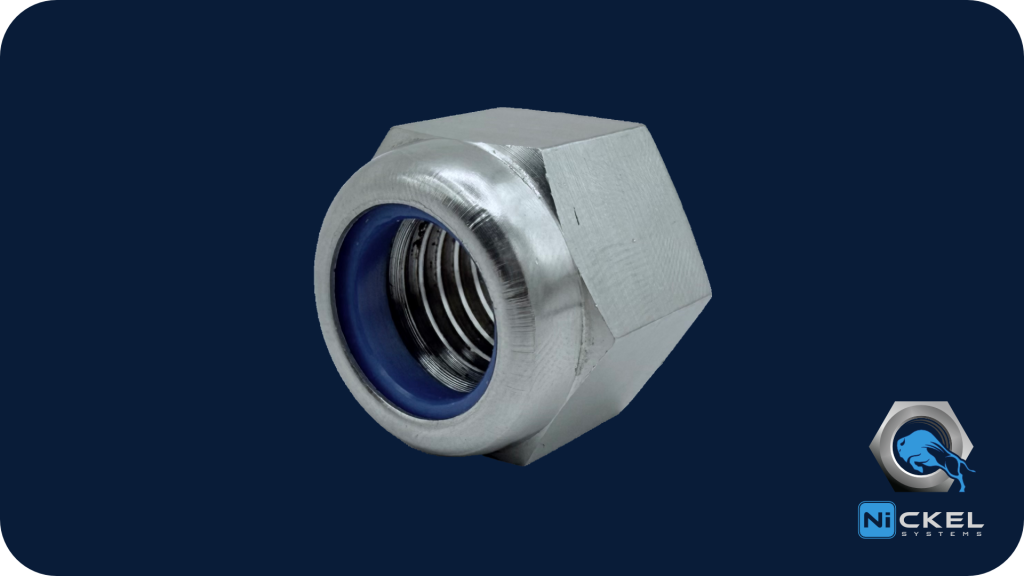

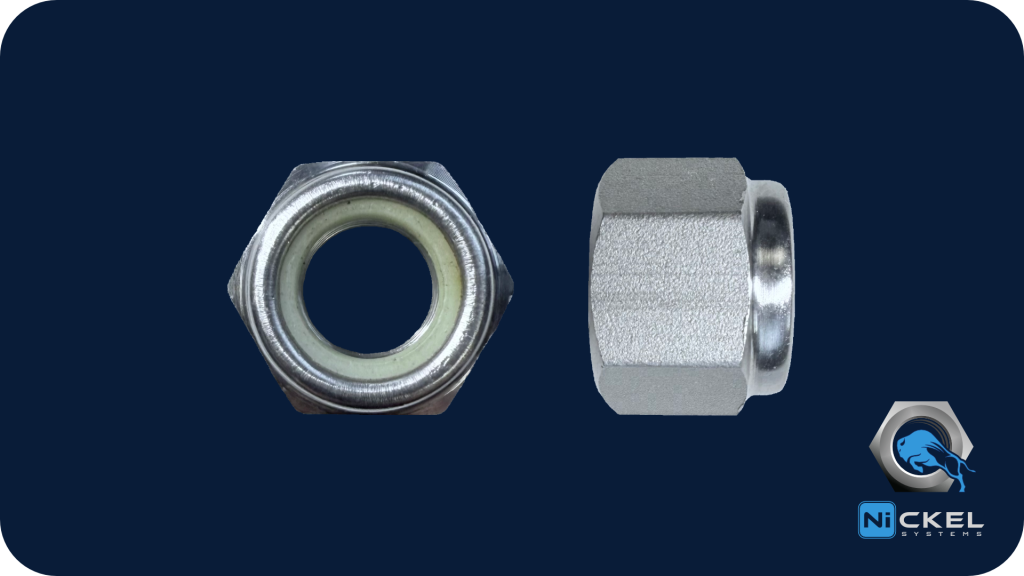

When the danger of corrosion is not too severe and 18-8 or 316 Stainless is adequate for fastening, we would offer nylon insert locknuts. These nuts feature a nylon ring that compresses against the bolt threads as the nut is tightened.

In instances where common stainless steel would not be adequate to withstand corrosion and a locknut would be required, we would recommend a top-lock nut. These nuts are produced by crimping the top thread of a standard hex nut. When top-lock nuts are assembled, they should spin freely until the lead thread of the bolt meets the distorted thread in the nut. The more the nut is torqued from this point, the greater the effort for disassembly becomes.

Types of Lock Nuts

There are several types of lock nuts. Each one has its unique locking mechanism.

- Nylon insert lock nut: This nut contains a nylon ring that deforms to grip the bolt threads. It has good vibration resistance. However, it is not reusable and the nylon wears out.

- All-metal lock nut: This lock nut uses deformed threads or friction-fit metal sections. It is designed for high-temperature applications and is much more durable than typical nylon lock nuts.

- Prevailing torque lock nut: These nuts resist turning without external pressure due to a non-threaded interference section. It is used in high-vibration settings.

- Serrated flange lock nut: These nuts have a wide, serrated base that bites into the surface material to prevent loosening. It is best when marring of the mating surface is acceptable.

- Castle nut /slotted nut: This is used with a cotter pin and drilled bolt for mechanical locking. It is most common in automotive and aerospace applications.

Industries and Applications

Lock nuts provide secure, vibration-resistant fastening in a wide range of sectors. Their locking features help maintain reliable connections and reduce the need for frequent retightening, even in challenging service conditions.

Automotive

Lock nuts support the safety and longevity of automotive assemblies exposed to dynamic movement and vibration.

- Applications: Transmission housings, mounting brackets, suspension linkages, steering, braking and exhaust systems, turbo assemblies, chassis assemblies

- Materials: Stainless steel, aluminum alloys, Hastelloy®, Inconel®

Aerospace

In aerospace applications, lock nuts are critical in maintaining fastener integrity under extreme thermal and mechanical stresses.

- Applications: Airframe joints, landing gear, engine assemblies, actuator connections, braking systems, interior components

- Materials: Titanium alloys, Inconel®, Alloy A286, 17-4 PH and 316 stainless steel

Construction

Lock nuts help maintain structural integrity in buildings, bridges and heavy equipment exposed to dynamic loads, thermal cycling and environmental challenges.

- Applications: Steel frames, bridge structures, cranes, heavy machinery

- Materials: Stainless steel alloys

Manufacturing and Machinery

Lock nuts secure fasteners in moving parts and industrial equipment, preventing loosening in high-vibration operations.

- Applications: Conveyor systems, presses, pumps, rotating equipment, gearboxes, stamping systems

- Materials: Alloy A286, Hastelloy®, Carpenter® 20, Inconel®, Haynes® 242®

Guidelines for Choosing Lock Nuts

Consider these best practices to optimize performance and reliability when selecting lock nuts for your project:

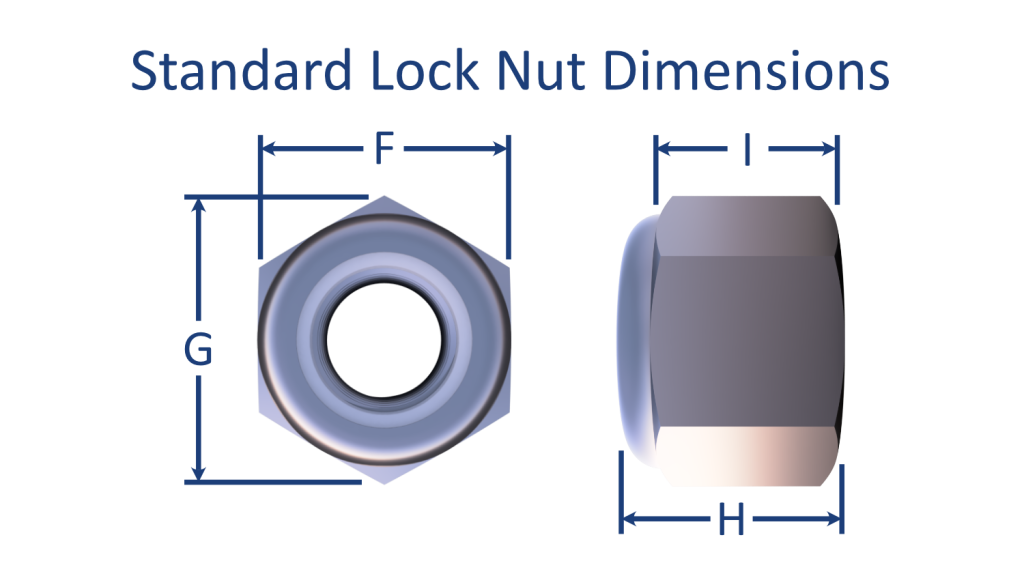

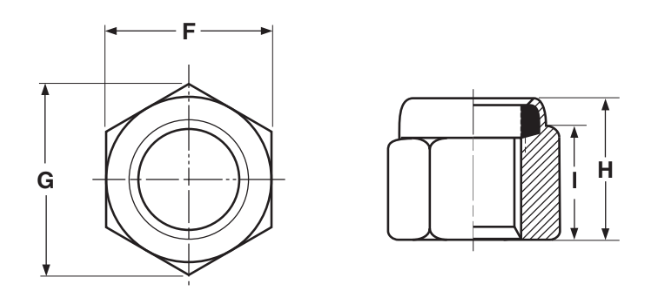

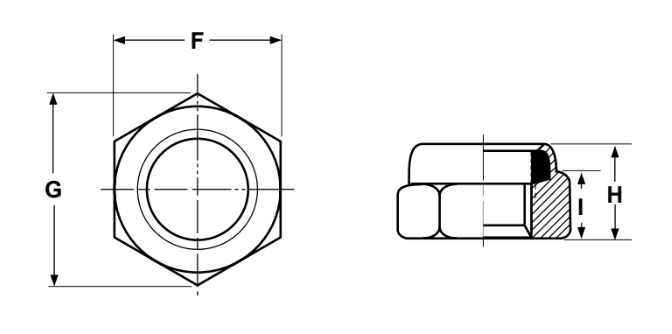

- Verify thread compatibility and dimensions: Confirm that the lock nut’s thread size, pitch and height precisely match your bolt or stud to ensure proper fit and secure fastening.

- Choose the appropriate material: Select materials that offer the necessary strength and corrosion resistance for your application environment.

- Specify suitable finishes: Determine if additional coatings or finishes are required to protect against wear, corrosion or harsh operating conditions.

- Match the locking mechanism to operating conditions: Consider the vibration levels, temperature range and maintenance access to choose the locking style that provides the best resistance to loosening.

- Account for temperature limitations: For high-temperature applications, choose all-metal lock nuts over nylon inserts, which can degrade and lose locking effectiveness under heat.

- Consult for custom requirements: When standard options do not meet your project’s specific demands, engage Nickel Systems for custom sizes, materials or finishes.