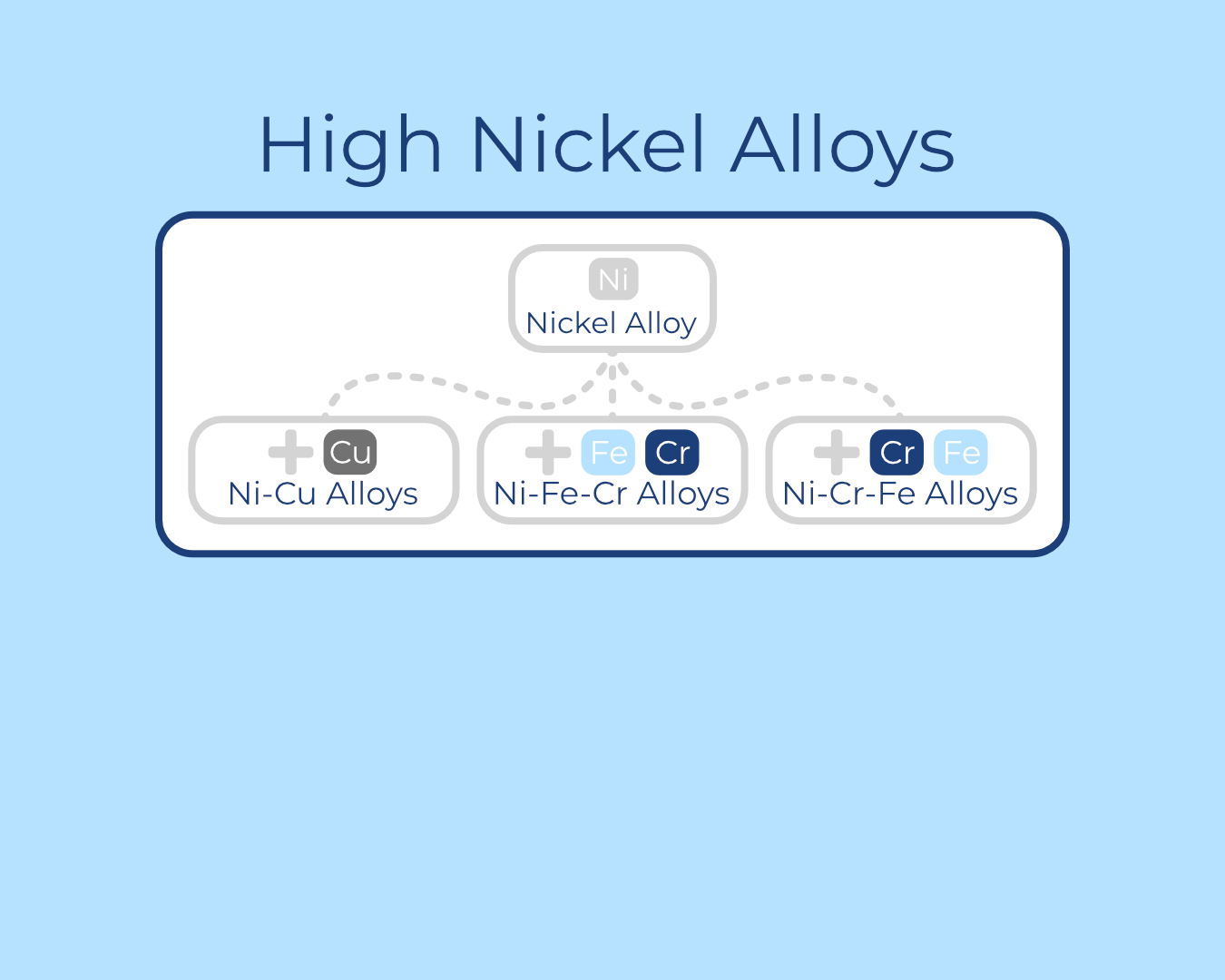

What is Hastelloy® X?

Hastelloy X is a nickel based superalloy in the nickel-chromium-iron-molybdenum family. It is known for its excellent high-temperature strength, oxidation resistance, and fabricability. It’s primarily used in environments that require durability at elevated temperatures, such as aerospace, gas turbines, and industrial furnaces.

Hastelloy® X Key Characteristics

- High Temperature Strength: Hastelloy® X maintains strength and structural integrity up to 2,200℉ (1,200℃).

- Oxidation Resistance: Hastelloy® X resists oxidation and corrosion even in harsh atmospheres.

- Hastelloy® X has good formability and weldability. This is unique compared to other high-temperature alloys.

Other Names & Designations for Hastelloy® X

- UNS N06002

- Alloy X

- Inconel® HX

- W.-Nr. 2.4665

Applications Using Hastelloy® X

Hastelloy® X fasteners are used in demanding, high-temperature environments where corrosion resistance, oxidation resistance, and mechanical strength are critical. Check out some applications and their descriptions below using Hastelloy® X fasteners.

Aircraft Engine Assemblies and Exhaust Systems

The Aerospace industry uses Hastelloy® X fasteners because of their high strength and thermal stability up to 2,200℉ (1,200℃). Socket head cap screws secure turbine engine casings and afterburner mounting. They also use hex head bolts and finished hex nuts for combustion liners and heat shields. They also use hex head bolts and finished hex nuts in combustion liners and heat shields.

Gas Turbine Exhaust Structures

The Power Generation Industry uses Hastelloy® X fasteners because of their excellent oxidation resistance and creep strength under thermal cycling. It uses fully threaded studs for flange to flange connections in hot sections and flat washers to distribute load and minimize thermal distortion.

Chemical Processing

The Chemical Processing industry uses Hastelloy® X fasteners to resist oxidizing and reducing agents in high-temperature chemical flows. Socket head cap screws and set screws to secure internal components. Heavy hex bolts and heavy hex nuts are bolted to external flanges and joints exposed to aggressive media.

Purchasing Hastelloy® X Fasteners

Hastelloy® X fasteners are specialty components used where both high heat and corrosive environments are present. Specific fastener types—hex head bolts, socket head cap screws, and finished hex nuts—are chosen based on the mechanical load, space constraints, and accessibility within high-performance systems.

Request a Quote