Titanium Gr2, Titanium Gr5, Titanium Gr7

UNS R50400, UNS R56400, UNS R52400

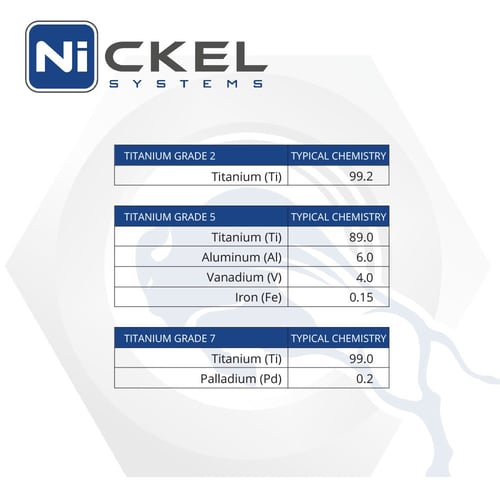

Grade 2 titanium is commercially pure titanium. When its surface is exposed to oxygen or moisture, a new corrosion resistant layer of titanium oxide is created. It resists both acids (oxidizing and mildly reducing) and alkali. Usage of Grade 2 titanium fasteners in marine environments is common. Grade 2 titanium fasteners are used for orthopedic and dental implants. Although non-toxic, its chips are extremely flammable.

The advantage of Grade 5 titanium is that it is heat treatable. Although it is more than twice as strong as Grade 2 titanium, its corrosion resistance is not quite as good.

A small addition of palladium is used to create Grade 7 titanium. This addition gives it better corrosion resistance than Grade 2 titanium fasteners in cryogenic and highly acidic environments.

Titanium Fasteners

- Lock Nuts

- Set Screws

- Dowel Pins

- Pipe Plugs

- Vented Screws

- 12-Pt Flange Screws

- Custom Fasteners

Specifications

- Plate, Sheet & Strip: ASTM B575, ASME SB575

- Rod & Bar: ASTM B574, ASME SB574

Material Properties

Technical Data Sheets

Industries & Applications

Ready to order or have questions?

What Our Customers Are Saying About Nickel Systems

“Nickel Systems is proving to be a great supplier in our supply base.”

“Thanks for all your help. Your bolts prevented a plant shut down. I’m happy and they are extremely happy.”

“Thanks, you save me AGAIN!!! That is why YOU are the BEST! Thank you so much!”

“Thank you to you and your team, for efforts above and beyond! It is much appreciated.”