Hastelloy X750

UNS N07750

Hastelloy X750 is a precipitation-hardenable nickel-chromium alloy used for its corrosion and oxidation resistance and high strength at temperatures to 1300°F. Although much of the effect of precipitation hardening is lost with increasing temperature over 1300°F, heat-treated material has useful strength up to 1800°F. Hastelloy X750 also has excellent properties down to cryogenic temperatures.

Hastelloy X750 applications include gas turbines, rotor blades, wheels, bolts and other structural components. Hastelloy X750 is also used in rocket-engine thrust chambers. Airframe applications such as thrust reversers and hot-air duct systems. Pressure vessel applications are formed from Hastelloy X750. Other applications are heat-treating fixtures, forming tools, extrusion dies and test machine grips. For springs and fasteners, Hastelloy X750 is used from sub-zero to 1200°F.

Hastelloy X750 Fasteners

- Hex Bolts

- Socket Cap Screws

- Hex Nuts

- Lock Nuts

- Washers

- Set Screws

- Custom Fasteners

Specifications

- ASTM B637 & ASME SB637

- Plate, Sheet & Strip: AMS 5542/5598

- Rod & Bar: AMS 5667

- W-Nr 2.4669

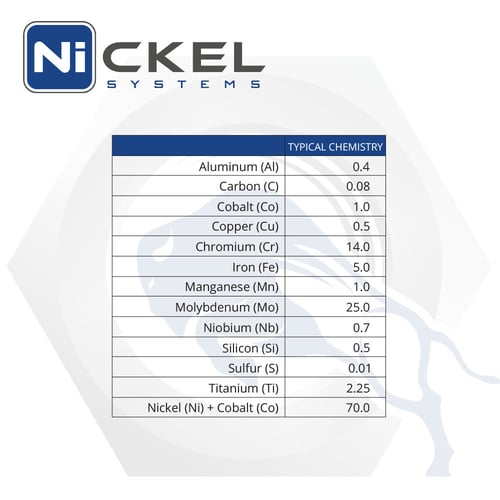

Material Properties

Technical Data Sheet

Industries & Applications

- Electronics & Semi-Conductors

- Oil & Gas

Ready to order or have questions?

What Our Customers Are Saying About Nickel Systems

“Nickel Systems is proving to be a great supplier in our supply base.”

“Thanks for all your help. Your bolts prevented a plant shut down. I’m happy and they are extremely happy.”

“Thanks, you save me AGAIN!!! That is why YOU are the BEST! Thank you so much!”

“Thank you to you and your team, for efforts above and beyond! It is much appreciated.”