- Home

- Industries

- Chemical Processing

Fasteners for Chemical Processing

An estimated 10 billion bearings are manufactured annually, and about 50 million of these are removed from service due to damage. Chemical processing environments are some of the harshest in the world due to their high temperatures, pressure and corrosive chemicals. Any fasteners used in these settings must be chemically resistant and maintain their durability, reliability and longevity.

These fasteners are made from materials hand-picked for their resistance to chemical degradation. Selecting the ideal material for your application depends on your unique environment.

Corrosion experts and chemical engineers worldwide demand Hastelloy®, Inconel® and Monel® fasteners. Industry giants Afton Chemical, DOW, Monsanto and Westlake Chemical rely on our superior service and extensive expertise to meet their critical, time-sensitive requirements.

The Science Behind Chemical-Resistant Fasteners

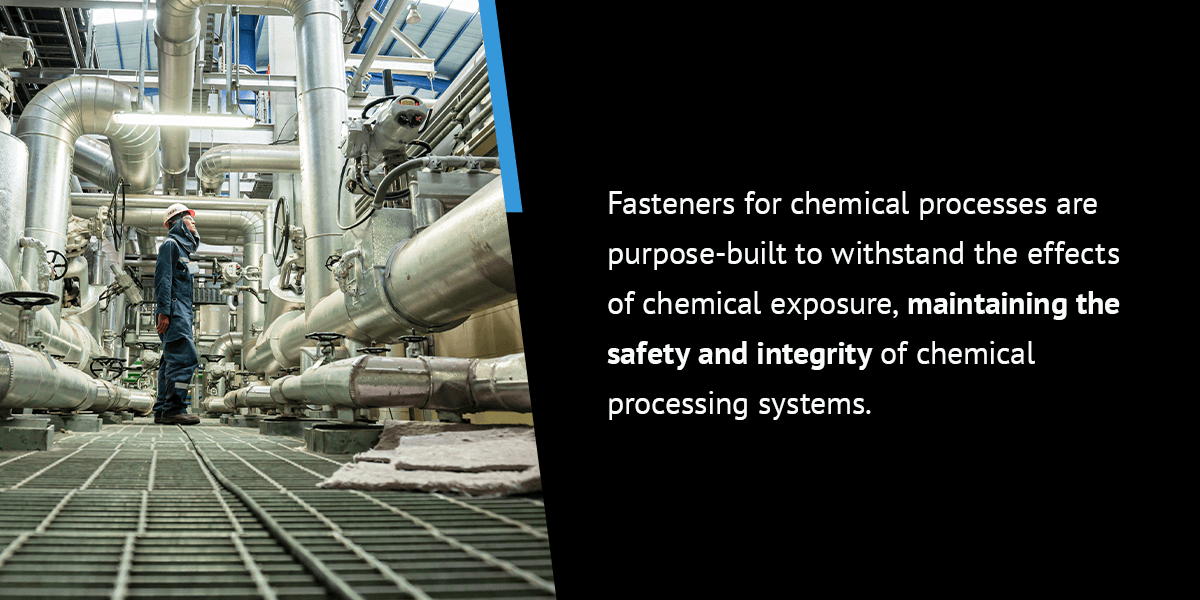

Fasteners for chemical processes are specialized components designed to join and secure chemical handling and processing equipment. They are purpose-built to withstand the effects of chemical exposure, maintaining the safety and integrity of chemical processing systems. Anything from a chemistry bolt to a nut or screw in a chemical processing machine is considered a fastener.

These fasteners are made from materials that can withstand various corrosive chemicals, including chemical alloys like stainless steel and non-metallic compounds like polypropylene. They may also have specialized coatings and treatments to provide additional corrosion protection and extend the components' useful life.

Contact us now for your immediate needs!

Some areas where Nickel Systems’ hardware is used:

- Aluminum Hydroxide Al(OH)3: Used in gas purification, water purification and making polyethylene.

- Chlorine (Cl): Used to manufacture polyvinyl chlorides and other chemicals to make plastics. Used as a disinfectant, chlorine and chlorine compounds are used for cleaning and sanitary uses in swimming pools.

- Ethylene (C2H4): This common chemical is widespread in the chemical industry and its worldwide production exceeds that of any other organic compound.

- Hydrochloric Acid (HCl): Used as a chemical reagent in large-scale production of vinyl chloride for PVC plastics and polyurethane. It is used in pickling lines at steel mills, household cleaning products and gelatins.

- Hydrofluoric Acid (HF): This is a precursor to most fluorine compounds including pharmaceuticals such as fluoxetine, PTFE and elemental fluorine. It is colorless, highly corrosive and capable of dissolving many materials.

- Sodium Hydroxide (NaOH): Also known as caustic soda, this chemical is used in many industries as a building block chemical for manufacturing pulp and paper, textiles, drinking water, soaps, detergents and other cleaners.

- Sodium Hypochlorite (NaClO): When dissolved in water, this chemical is commonly known as bleach or liquid bleach. It is frequently used as a disinfectant in the water works and wastewater industries.

- Sulfuric Acid (H2SO4): This is an essential chemical in manufacturing fertilizers and battery acid. It's also used to make other chemicals, including synthetic detergents, explosives and nitric acid.

Selecting the Best Fasteners for Chemical Processing

Fasteners are the backbone of chemical processing equipment, from storage and transportation to machine components. Each fastener must meet stringent requirements to maintain a safe and effective chemical processing environment. Some critical considerations for chemical-resistant fasteners include:

- Corrosion resistance: Fasteners are exposed to various corrosive chemicals in the chemical processing industry, making material selection essential. They must be constructed from corrosion-resistant material, such as Inconel, titanium and stainless steel.

- Durability: Fasteners must withstand the intense heat and high pressure of the chemical industry. Look for high strength that allows them to maintain their integrity in harsh conditions.

- Temperature resistance: Some chemical processing applications require temperatures of up to 1000 degrees Fahrenheit, requiring fasteners made from materials up to the task.

- Reliability: When working with potentially hazardous chemicals, every component must meet the relevant quality standards to ensure worker safety.

- Leak prevention: Maintaining airtight connections is essential for any chemical environment, and a minor leak can have significant consequences. Your fasteners must be high quality and adequately tightened to their precise specifications.

Hastelloy® C276 Fasteners: The Ultimate Solution for Chemical Environments

The Hastelloy® C276 alloy is a popular and versatile nickel alloy. Hastelloy® fasteners are preferred in chemical environments due to their chemical-resistant properties in applications such as sulfuric acid, hydrochloric acid, hydrogen sulfide, wet chloride gas and chlorine dioxide. They also maintain excellent mechanical properties in temperatures up to 1500 degrees Fahrenheit — perfect for hot and corrosive chemical processing environments.

Some of the benefits of Hastelloy® C276 for chemical processing include:

- Excellent resistance to strong reducing and moderately oxidizing corrosive acids.

- Superior stress corrosion cracking resistance.

- Good resistance to localized chemical attack.

- Exceptional corrosion resistance to organic acids, reducing acids, seawater, brine, oxidizing and chloride-containing media, and sulfuric flue gases.

Partner With Nickel Systems for High-Quality Fasteners

The chemical processing industry relies on the highest quality fasteners to maintain safety and product integrity, no matter how challenging the environment. As the largest stocking distributor of exotic alloy fasteners, Nickel Systems has high nickel alloy fasteners in stock and ready for you to purchase. Our materials have a proven track record in some of the most demanding environments, often the preferred choice in severe corrosion and heat-resistant applications.

Reach out to us today to learn more.