Incoloy 800, 800HT

UNS N08800

The 800 series alloys were developed during the 1950s. At that time, nickel was in high demand for national defense. In order to create a heat-resistant and corrosion-resistant material for commercial use with a lower nickel content, the 800 series alloys were created.

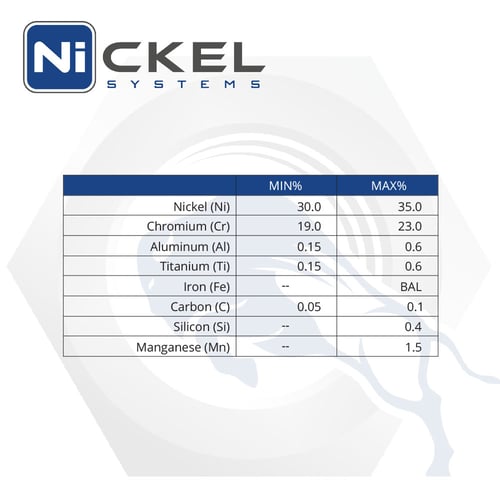

Incoloy 800 has 2 notable variations. Alloy 800H (UNS N08810) restricts the carbon content to the higher end of the acceptable range of Incoloy 800. Alloy 800 HT (UNS N08811) restricts the carbon, aluminum and titanium contents all to the high end. The advantage of the restricted chemistry results in higher creep strength and stress rupture properties. In our experience, most material purchased as Incoloy 800 also qualifies as Alloy 800H and Alloy 800HT.

Environments where Incoloy 800 fasteners have been used range from cryogenic to 1500º F (800º C). Alloy 800H and 800HT increase this range. Incoloy 800 is particularly resistant to nitric acid and is used in the chemical and petrochemical industries.

Incoloy 800 Fasteners

- Lock Nuts

- Set Screws

- Dowel Pins

- Pipe Plugs

- Vented Screws

- 12-Pt Flange Screws

- Custom Fasteners

Specifications

- Plate: ASTM B240, ASME SB240

- Bar: ASTM B408, ASME SB408

Material Properties

Technical Data Sheet

Industries & Applications

- Air Pollution Control

- Chemical Processing

- Oil & Gas

- Power Generation

Ready to order or have questions?

What Our Customers Are Saying About Nickel Systems

“Nickel Systems is proving to be a great supplier in our supply base.”

“Thanks for all your help. Your bolts prevented a plant shut down. I’m happy and they are extremely happy.”

“Thanks, you save me AGAIN!!! That is why YOU are the BEST! Thank you so much!”

“Thank you to you and your team, for efforts above and beyond! It is much appreciated.”